...

2025-08-16 09:41

1956

...

2025-08-16 09:29

1492

...

2025-08-16 09:07

287

...

2025-08-16 08:56

115

...

2025-08-16 08:02

2963

...

2025-08-16 07:49

994

...

2025-08-16 07:34

2659

...

2025-08-16 07:31

1356

...

2025-08-16 07:24

1294

...

2025-08-16 07:16

2690

- In conclusion, fiberglass sewer pipes represent the future of underground infrastructure due to their exceptional strength, durability, and environmental benefits. As technology continues to advance, we can expect to see even more innovative uses for fiberglass materials in sewer systems and other applications. Fiberglass is truly a game-changer in the world of civil engineering and urban infrastructure.

- Another key benefit of fiberglass chemical tanks is their durability. Fiberglass-reinforced plastic is a strong and robust material that can withstand heavy loads and harsh conditions without cracking or breaking. This makes fiberglass tanks suitable for use in a wide range of applications, including water treatment plants, chemical processing plants, and industrial facilities.

- Our hand jack hammers are engineered with precision and durability in mind, ensuring that every swing packs a powerful punch. They feature ergonomic handles designed to minimize vibrations, providing comfort and reducing user fatigue during extended use. The balanced design allows for precise control, making it easier to target specific areas without causing unnecessary damage to surrounding materials.

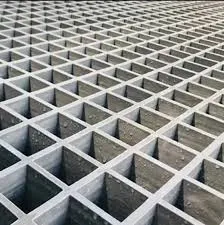

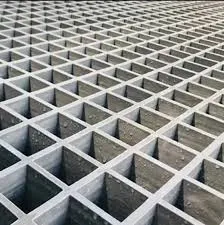

What Are The Performance Advantages Of Fiberglass Grating

- The manufacturing process of drill rod steel involves several stages, starting with the selection of high-quality raw materials. These are then subjected to heat treatment, including quenching and tempering, to achieve the desired hardness and toughness. The rods are then precisely machined to ensure accurate dimensions and a smooth surface finish, reducing friction during drilling.

- The manufacturing process of fiberglass water tanks is a testament to human innovation. It begins with layers of fiberglass strands that are woven together to form a mat. This mat is then soaked in a resin bath, a mixture of polyester or vinylester resins along with catalysts and other additives designed to enhance strength and flexibility. The saturated fiberglass is cut into specific shapes and assembled around a mold, layer by layer, until the desired thickness is achieved. Each layer is carefully consolidated using rollers to remove any air pockets and ensure maximum adhesion between the fibers and the resin.

- His tenacity paid off when he developed an innovative technology that revolutionized the way people interacted with their environment

Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas

Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas drilling through rock. Moreover, the use of real-time data analysis allows operators to make adjustments on the fly, optimizing the drilling process for maximum effectiveness.

drilling through rock. Moreover, the use of real-time data analysis allows operators to make adjustments on the fly, optimizing the drilling process for maximum effectiveness. The buttons, which are made of tungsten carbide, are strategically placed on the bit body to create a cutting surface that is both aggressive and efficient The buttons, which are made of tungsten carbide, are strategically placed on the bit body to create a cutting surface that is both aggressive and efficient

The buttons, which are made of tungsten carbide, are strategically placed on the bit body to create a cutting surface that is both aggressive and efficient The buttons, which are made of tungsten carbide, are strategically placed on the bit body to create a cutting surface that is both aggressive and efficient tungsten carbide button bits. As the bit rotates, the buttons shear through the rock, breaking it into small pieces that can be easily removed.

tungsten carbide button bits. As the bit rotates, the buttons shear through the rock, breaking it into small pieces that can be easily removed.FIBERGLASS COVERED GRATING

This flexibility makes it a popular choice among professionals in fields such as construction, mining, and geology This flexibility makes it a popular choice among professionals in fields such as construction, mining, and geology

This flexibility makes it a popular choice among professionals in fields such as construction, mining, and geology This flexibility makes it a popular choice among professionals in fields such as construction, mining, and geology anchor drill bit.

anchor drill bit.FRP grating is very lightweight, making it easy to store and transport. This is a big benefit as most construction materials are heavy and bulky, making them harder to move around.